With the continuous improvement of modern science and technology, the manufacturing technology of conveyor belts is gradually improved, the manufacturing quality is also further improved, and the service life and replacement cycle of conveyor belts have been extended to varying degrees. In the actual production and equipment use, the conveyor belt replacement and the need to redo the joint work of the conveyor belt repair project rate is very small, most of the maintenance projects are based on the conveyor belt scratch repair, improve the quality of coal and Equipment inspection management to strengthen, so that long-distance conveyor belt tear rarely occur, according to our company in recent years, the conveyor belt running statistics show that the degree of damage within the conveyor belt within 500 mm 85% of the total, which It is also the main task of daily maintenance of the conveyor belt.

The main tool for thermal repair of conveyor belts is a vulcanizing machine. Depending on the size of the belts, the vulcanizing machine is divided into several models. Large vulcanizers are required for the installation and replacement of belts and for the longer tearing sites, but for machines up to 500 mm Of the tear, the use of large vulcanizing machine is unwise, not only to use heavy block and heat repair plate, a large area of heat-repair radiation damage to the conveyor belt aggravate the more serious is to increase the demolition care Roller bracket and pull conveyor configuration of the operating aspects, increasing the labor intensity of maintenance personnel, resulting in energy waste and maintenance costs rise, extending maintenance downtime. For the length of less than 500 mm damaged parts of the conveyor belt repair, using a well-known domestic manufacturer Wuxi Fuda Vulcanizer Manufacturing Co., Ltd. production of vulcanizing repair device, it is a simple type of small repair machine, with small size, light weight, easy to operate , Vulcanization quality can meet the technical requirements and other characteristics, but also lifting and transportation and mining machinery used and maintenance unit must have one of the common tools.

- The type and working principle of sulfur curer

Currently on the market more common thermal repair Mending device to force the way is divided into two kinds, one is screw-type pressure device repairer, and the other is a hydraulic cylinder pressure device repair device. Screw-type mechanical pressure repair device by the screw mechanism (including the upper and lower plate), pressure plate, the upper and lower heating plate and the rack composition, easy to use, easy to operate, not affected by the conveyor belt repair face angle, pressure stability Features, widely used in the field. Hydraulic pressure repair device using direct hydraulic cylinder pressure from the hydraulic cylinder, up and down the heating plate and the rack structure, do not need pumps, hydraulic plate and other subsidiary bodies, more effort, but the face of the high angle requirements, Heating plate temperature conduction of hydraulic cylinders have a certain impact on the ambient temperature is also higher, the general use of the ambient temperature is not less than 5 ℃, it is difficult to adapt to the production site, so rarely used. The same applies to the large-scale vulcanizer. Generally, the work of repairing the conveyor belt is maintained at a working pressure of 1.0 to 1.2 MPa. When the temperature is between 140 ° C and 145 ° C, the vulcanization quality can be guaranteed.

2. repaired the use of the process of problems

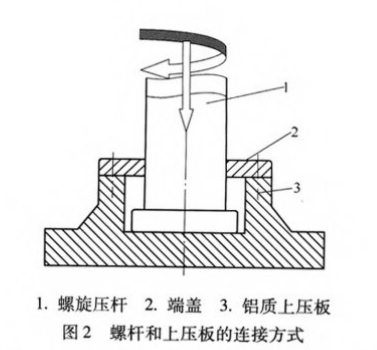

The composition of the thermal repair patch, see Figure 1, including the upper and lower pallet, up and down the heating plate, pressure plate, herringbone rack, power control box. Figure 1 thermal repair patch on the pallet and a screw connected to the screw through the rotation to adjust the distance between the upper and lower heating plate to adapt to the different thickness of the conveyor belt and conveyor belt vulcanization site preload in the vulcanization process to withstand 1.0 ~ 1.2 MPa pressure. Due to the large number of loading and unloading process equipment, equipment operation time is longer, the repair work carried out by using the repair device is also larger, frequent operation leads to repair device screw rotation is not flexible, resistance is great, severe bending of the screw, the impact Normal use. Screw replacement several times, the effect is not satisfactory, and sometimes in order to grab the time, had to use a large repair machine, maintenance efficiency is low.

Since 2001, as professional we manufacture high quality machines at best price!

Address: Guangming industrial zone, Xibei town, Wuxi city, Jiangsu Province, China 214194

Mobile & WhatsApp: 86-15995216108 Skype: live:alex-fudamachine

Email: alexmachine@yeah.net & alex-fudamachine@hotmail.com

Website: wuxifuda.en.alibaba.com & www.conveyorbeltvulcanizer.com