- Improvements

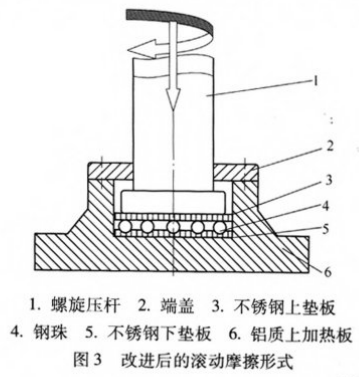

In view of the problems in use, the tinker repaired and measured were disassembled, the working principle was analyzed, the hidden troubles of parts and components were investigated, and the main factors that caused the screw damage and disassembly were found out. Screw and the plate is connected to the surface contact with the hinge mode, see Figure 2.1. Spiral pressure rod 2. Cover 3. Aluminum on the plate Figure 2 screw and the pressure plate connected to the screw rod is generally 45 steel or 40Cr material made into a rectangular thread, to ensure its strength and toughness; on the plate with cast aluminum to reduce repair weight. Screw by rotating the upper plate to complete the move up and down. Initially set the pre-pressure screw end and upper plate friction is relatively small, more flexible rotation, but after the repair device to complete repair, due to the upper and lower heating plate also retains the remaining temperature of about 120 ℃, due to thermal expansion and contraction phenomenon , Even if the pressure plate pressure relief is completed, the upper and lower heating plate also exists between the larger pressure on-site repair can not wait until the heating plate temperature dropped to the initial temperature before repair and then remove the repair device, the need to promptly evacuated, bound to belt Under the circumstance of pressure, the material of the rotating screw disassembly and repairing equipment and the screw and the aluminum heating plate are greatly different in hardness. Frequent use leads to the aggravation of wear on the groove of the pressing plate and the increase of the friction force, resulting in the rotation difficulty and the worsening of the weariness Circulation, serious damage to the screw bending, the impact of repair device use. The device has been partially rebuilt to reduce the friction by reducing the friction factor under unavoidable pressure conditions. Simple Thrust Bearing Design Considered on Trimmer Aluminum Upper Platen 1. Helical Bar 2. End Cap 3. Stainless Steel Upper Plate 4. Ball 5. Stainless Steel Lower Plate 6. Aluminum Upper Plate Figure 3 Improvements After the rolling friction seat seat with a thickness of 2 to 3 mm below the stainless steel circular plate to avoid the wear on the aluminum plate, the middle of laying 3 mm number of steel balls, apply a small amount of grease, and then covered in a 2 ~ 3 mm stainless steel plate. Finally install the screw and pressure plate cover, basically achieved rolling friction, as shown in Figure 3. After the transformation effect is very obvious, under pressure, the screw rotation is also very flexible, to eliminate the abnormal wear on the aluminum pressure plate, but also to solve the upper and lower pressure plate is not easy to center the problem.

- Conclusion

The simple modification of the repairer pressure device and the low reforming cost make this improved concept feasible and worthy of reference for the type of sulfur curer in use and also provide design reference for the repairer manufacturer. The design can be used directly molded thrust bearings to reduce the labor intensity of users and improve the competitiveness of products in the market.

Since 2001, as professional we manufacture high quality machines at best price!

Address: Guangming industrial zone, Xibei town, Wuxi city, Jiangsu Province, China 214194

Mobile & WhatsApp: 86-15995216108 Skype: live:alex-fudamachine

Email: alexmachine@yeah.net & alex-fudamachine@hotmail.com

Website: wuxifuda.en.alibaba.com & www.conveyorbeltvulcanizer.com